Coze offers three different displays of the data we gather during your product's inspection:

1.Summary

2.Report table

3.Product by product view

All of the displays update as the tester inspects the products, so you can Know what is happening in the factory in real time.

Following, are explanations about these three displays, and how you can get the most out of them.

1.Summary

2.Report table

3.Product by product view

All of the displays update as the tester inspects the products, so you can Know what is happening in the factory in real time.

Following, are explanations about these three displays, and how you can get the most out of them.

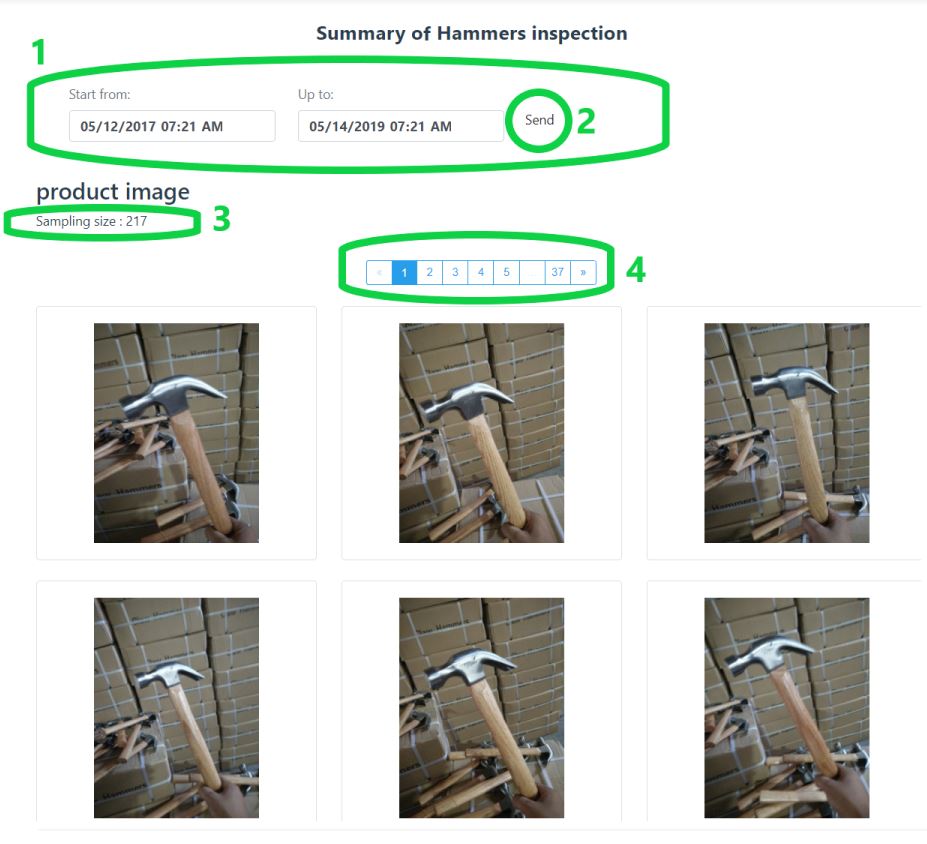

Our summary

On the summary you can see all the data the tester collects during the inspection, including graphs with statistical analysis of the results, pictures galleries, and inspected quantity of products.

|

1.If you want to see the results from a specific inspection you can always change the date of the summary to watch results from a specific date.

2.After you change the date, you you need to click the "send" button and the summary will present you with the relevant information.

3.Here you can see the quantity of the inspected numbers for the parameter.

4.These are the photos gallery pages. you can click on different pages numbers to browse through the gallery.

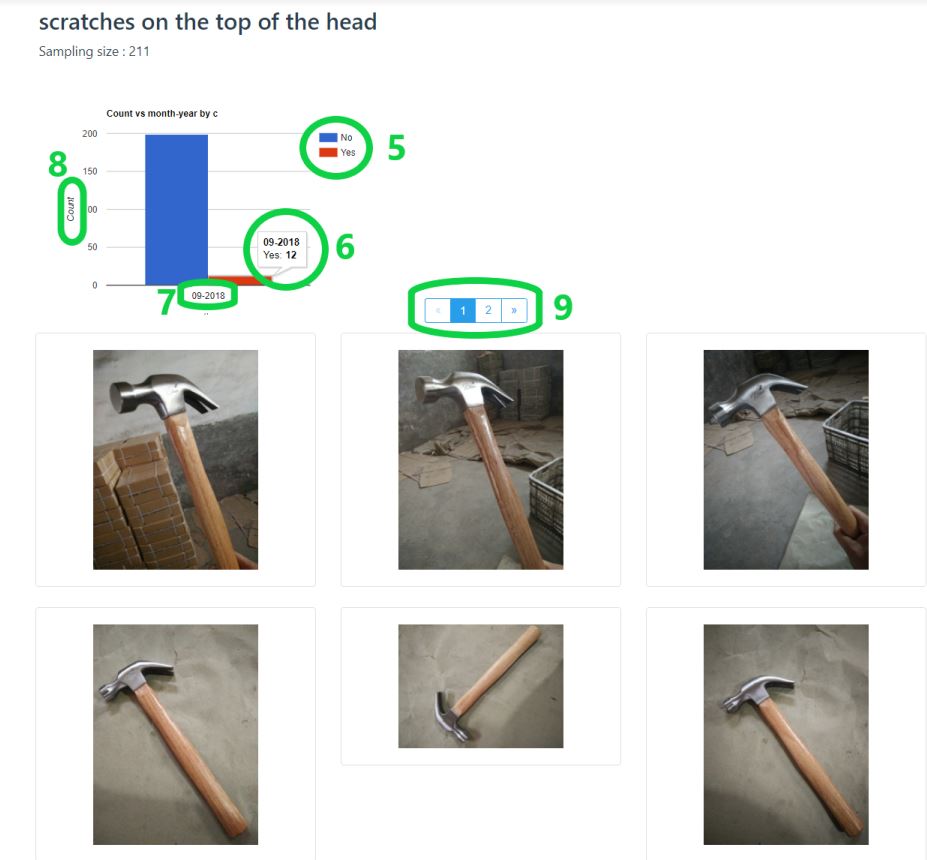

5.Here you can see the graph's index that tells you what each column represents. . The graph in the picture presents the quantity of products with scratches, while yes means there are scratches.

6.To see the exact number of the defected products, you can hover above the column with your mouse.

7.This is the date of the inspection. It might come in handy when you will have many inspections for the same product and you'd want to compare between them.

8.The count represents the quantity of products.

9.Below every graph that relates to visible defects you will see a gallery of defects' close up pictures.

|

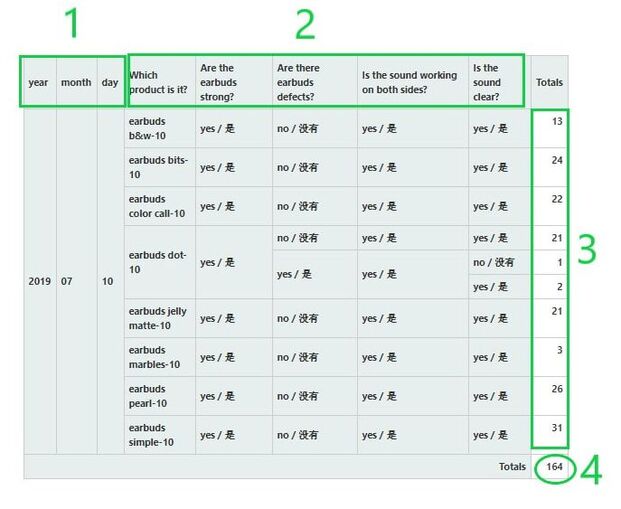

Our report.

The report enables a clear and simple comparison of the products in the inspection. whether there is a need to compare the product to it's spec, or to compare different product variations to each other, the report will concentrate all the required data in one table.

While every report is different, there are some common features you can see in all of our reports. For the explanation we will use a report from an earbuds inspection, in which we checked different types of earbuds by the same parameters.

While every report is different, there are some common features you can see in all of our reports. For the explanation we will use a report from an earbuds inspection, in which we checked different types of earbuds by the same parameters.

|

1.On the left side of the report you can see the date of the inspection.

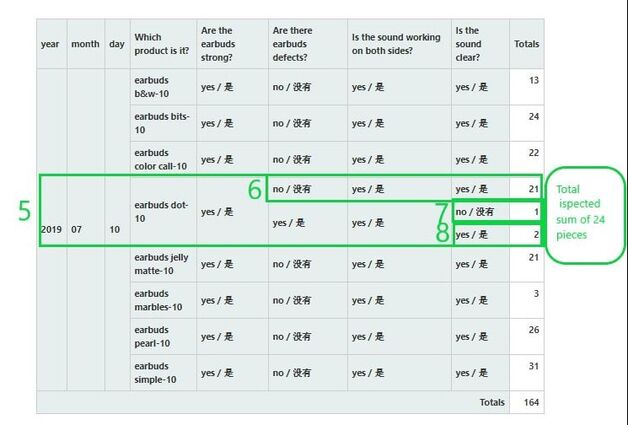

In case you ordered multiple inspections for the same product, you could see all of them in the table and differentiate by the date. 2.These are the parameters we inspected in the product. For example, our client wanted us to check if the earbuds are strong, if they have visual defects, if the sound is working on both sides and if it's clear. In this specific report there is another parameter which is the name of the product, since we checked more than one earbuds model. 3.This column shows the number of inspected items from each type. Products with the same characteristics / defects will be counted together (further explanations in the next picture). 4.This is the total sum of products which were inspected in this day of inspection, some inspections will have bigger inspected quantities, depending on the number of parameters, and their complexity. 5.Now we will explain about a specific line in the table, the line that shows the product "earbuds dot 10". you can see that the total sum of the inspected products from this earbuds model is 24 (we added up the numbers). The line of this model shows that all 24 pieces were strong, but for the other parameters, our tester found differences between the inspected items. 6.This line shows there are 21 pieces of earbuds that were strong, had no defects, and their sound was good. 7.This line shows there was one pair of earbuds that had visual defects and for which the sound wasn't clear. 8.On this line we can see 2 pairs of earbuds that had visual defects, but other than that, all other checks were ok. *You can see that our tester didn't find any problems with all of the other earbuds' models he checked on this inspection. |

Our conversations view.

The conversations view enables you to see every inspected product by itself, however, it doesn't provide statistic data about all of the inspection. in general.

This view will be useful if you have many products which are inspected by the same criteria but are difficult to differentiate based on their gallery photo alone.

The inspected parameters are the questions the tester is asked in the inspection, so in the conversations you can see the questions as the tester sees them, and the tester's answers.

This view will be useful if you have many products which are inspected by the same criteria but are difficult to differentiate based on their gallery photo alone.

The inspected parameters are the questions the tester is asked in the inspection, so in the conversations you can see the questions as the tester sees them, and the tester's answers.

|

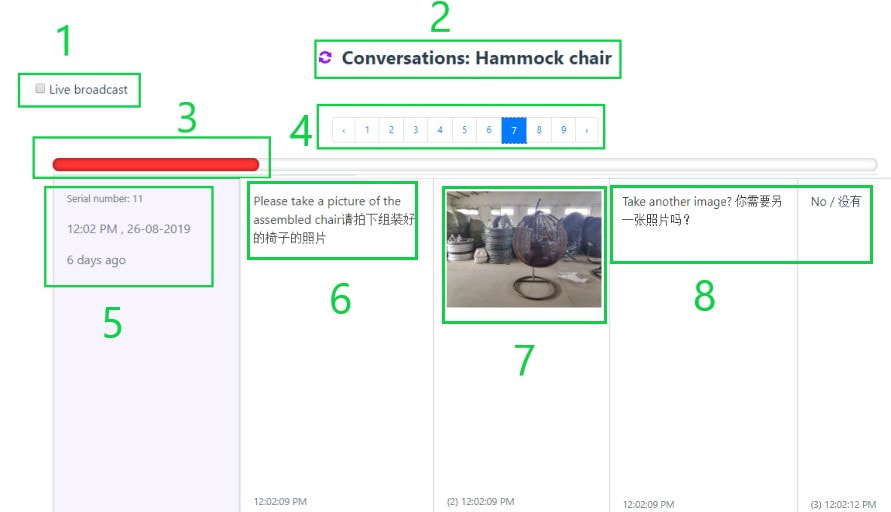

1.This is the live broadcast tick box.

It automatically refreshes the page every few seconds to show new conversations (product inspections). If you wish to stop the automatic refreshing you can un-tick the box. 2.This is the name of the inspection

3.This is a scroller, you can drag it from right to left to reveal the next questions & their answers.

4.These are the conversations pages, you can move one by one to watch all of the inspected products.

5.Here you can see some information about when the product was inspected.

6.This is the first question. In this case specifically the tester was asked to take a picture.

7.And, accordingly, this is the answer our tester answered to the previous question. Since the question was to take a picture, the answer is in the form of an image.

8.After taking a picture, the tester is asked if he needs to take another one, so this is what we are seeing here.

|

|